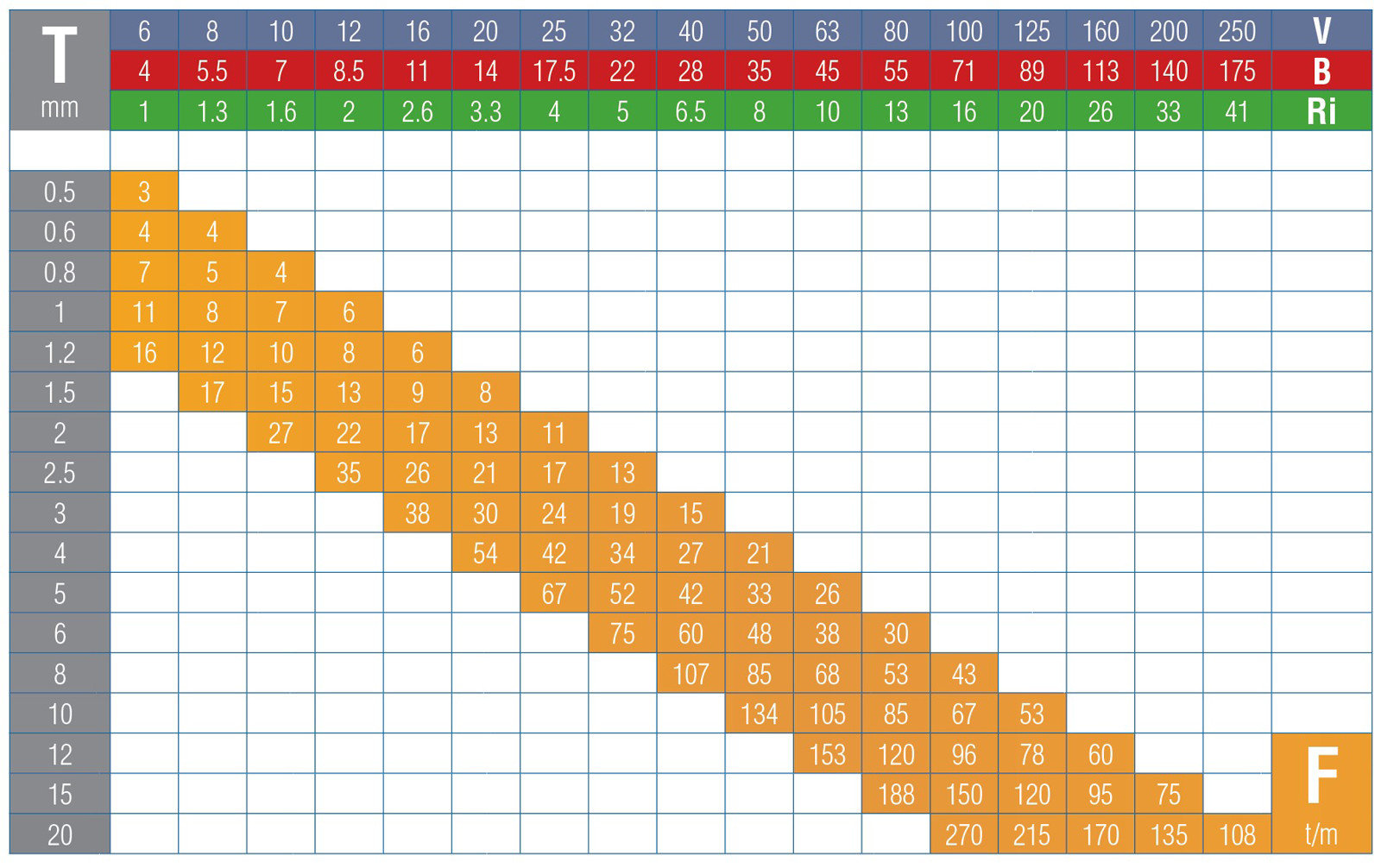

Each operation needs a certain tonnage per meter. You can also see the die width V (mm) that is needed for such specifications. The bending force table below helps you identify the minimum flange length b (mm) and inside radii ir (mm) according to material thickness t (mm). Air bending and bottoming account for around 90% of all bending jobs. V-bending is the most common bending method using a punch and die. It has three subgroups – bottoming, air bending and coining. Simpler methods are more flexible and most importantly, need fewer different tools for getting a result. The dilemma is usually between going for accuracy or simplicity, while the latter gets more usage.

Request a quote today, or contact Chicago Metal Rolled Products to learn more about our square tube bending capabilities.There are quite a few different bending methods available. Rolled square tubing can also be formed into helixes for use as stair stringers for spiral staircases. All types of structures are now built using bent square tubing, such as roofs, trellises, canopies, arches, balconies, and portals. Applications for Bent Square Tubeīent square tube is used in numerous OEM applications, including roll-over protection, framework, bumpers, and playground equipment.

In addition to square tube bending, we can also provide numerous ancillary operations, including saw cutting, drilling, welding, and more. Value-Added Services for Square Tube Bending Thanks to the variety of processes we can perform, our advanced machinery, and our library of tooling, customers rarely incur tooling charges on square tube bending projects. With dozens of machines and hundreds of die sets for square tube bending at our disposal, we can produce bent square tubing in sizes from 3/8” x 3/8” to 12” x 12”. Chicago Metal Rolled Products uses a variety of square tube bending techniques, including:

0 kommentar(er)

0 kommentar(er)